Chains

Chains are components for transmitting power by means of traction and are mainly used in transportation systems. There are several types of chains, so it is convenient to know their characteristics in order to know which is the most suitable for each use; some types are described below.

Need a Chain Distributor?

At BRR® Refacciones Industriales we are distributors of Chains for different States and Cities such as: Puebla, Querétaro, Edo de México, SLP (San Luis Potosí), Ciudad Valles, León Guanajuato and Toluca. We also have an online Cadenas store for the rest of the Mexican Republic.

What are the Chains?

A chain is a machine component, which transmits power by means of traction forces, and is mainly used for power transmission and conveyor systems.

The function and uses of the chain are similar to a belt. There are many types of chains.

It is convenient to classify the types of chains by material composition or method of construction.

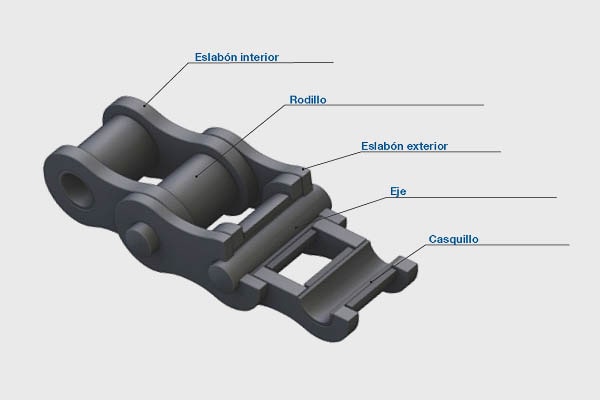

Parts of a Chain

Plate:

The plate is the component that supports the tension placed on the chain. This is usually a repeated load, sometimes accompanied by a shock. Therefore, the plate must have not only high static tensile strength, but also withstand dynamic loading and shock forces. In addition, the plate must meet environmental resistance requirements (e.g. corrosion, abrasion, etc.).

Chain pin:

The pin is subject to shear and bending forces transmitted by the plate. At the same time, it forms a load-bearing part, together with the bush, when the chain flexes during sprocket engagement. Therefore, the pin needs high tensile and shear strength, bending strength and must also have sufficient resistance against shock and wear.

Bushing (bushing):

The bush is subjected to shear and bending stresses transmitted by the plate and roller, and also receives shock loads when the chain engages the sprocket.

In addition, when the chain is articulated, the inner surface forms a load-bearing part together with the pin. The outer surface also forms a load-bearing part with the inner surface of the roller when the roller rotates on the rail or engages with the sprocket. Therefore, it must have high tensile strength against shear and be resistant to dynamic shock and wear.

Roller (roller):

The roller is subjected to the impact load when it strikes the sprocket teeth during the engagement of the chain with the sprocket. After engagement, the roller changes its point of contact and balance. It is held between the sprocket teeth and the roller, and moves over the tooth face while receiving a compressive load.

In addition, the inner surface of the roller constitutes a part of the bearing together with the outer surface of the roller when the roller rotates on the rail. Therefore, it must be wear resistant and have strength against shock, fatigue and compression.

Cotter pin, cotter pin, pin, spring clip, spring clip, T-pin

These are the parts that prevent the outer plate from falling off the chain pin at the connection point. They can wear during high-speed operation, therefore, for this application, these parts require heat treatment.

Chain Classification

- Power transmission chain

- Small pitch conveyor chain

- Precision conveyor chain

- Upper chain

- Free-flow chain

- Large pitch conveyor chain

The first one is used for power transmission, the other five are used for transport.

Drive Chain Nomenclatures

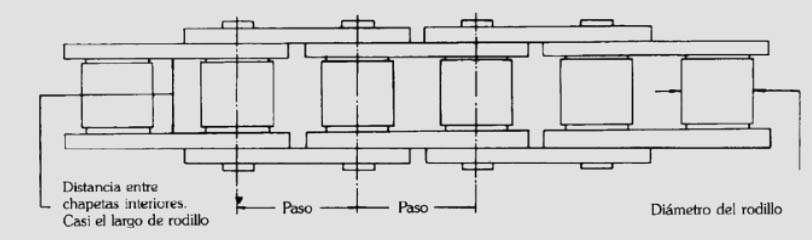

STEP or PITCH

This dimension is of major importance for chains and their sprockets.

It is expressed in inches as mentioned above but always taking into account the number of eighths of an inch contained in the aforementioned pitch so that for example chain number 40 (see important note below) has four eighths (4/8) or half an inch (1/2″). The number 50 chain has 5/8 pitch or 5/8 of an inch.

Number 60 has 6/8 pitch or three quarters of an inch (3/4″).

Number 80 has eight-eighths of a pitch (8/8) or one inch (1″). Number 100 is (10/8) or 1-1/4″. Number 120 is 12/8″ or 1-1/2″ and so consequently and successively numbers 140, 160, 200. They are manufactured up to number 240.

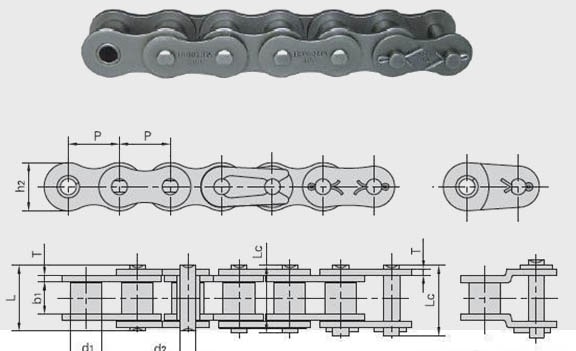

Basic structure of the power transmission chain:

Here is a typical configuration for the RS60 type chain