Electric Motors (Geared Motors, Electric Generators and Variable Speed Drives)

Electric motors are important alternatives to combustion engines, have been used for some time for various functions and have been among the greatest challenges in technology.

- What are Electric Motors?

- How does an electric motor work?

- What do Electric Motors consist of?

- Classification and Types of Electric Motors

- Types of Electric Motor Machine

- Functions and Applications of Electric Motors

- Electric Motor Brands

- Electric Motor Articles

- Electric Motors Catalogs

- Free Courses on Electric Motors

- Electric Motor Manuals

Do you need an Electric Motor Distributor?

At BRR® Refacciones Industriales we are distributors of Electric Motors for different States and Cities such as: Puebla, Querétaro, Edo de México, SLP (San Luis Potosí), Ciudad Valles, León Guanajuato and Toluca. In addition, we have an online store of Electric Motors for the rest of the Mexican Republic.

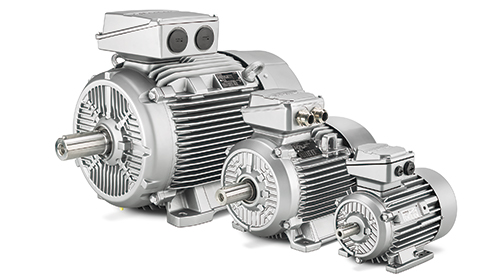

What are Electric Motors?

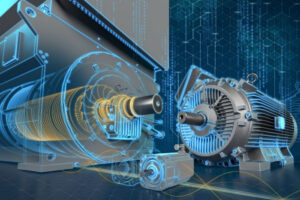

An electric motor is a machine with the ability to convert electrical energy into mechanical energy. It achieves this through the action of magnetic fields generated by components called coils inside the motor.

How does an Electric Motor work?

What do Electric Motors consist of?

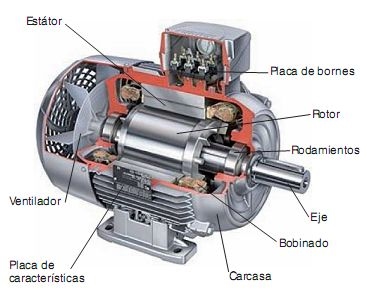

Electric motors have four main components:

Stator

It is the fixed part, it is a fundamental element for the transmission of power, or alternating current when talking about electric generators.

Rotor

It is the part that rotates inside the electric machine, consisting of a shaft that serves to support a set of coils that are wound on static pole pieces.

Switch

It is a kind of switch and its function is to periodically change the current direction between the external circuit and the rotor.

Brushes

They serve to establish a fixed connection between the rotor coils and the machine. Two rings are fixed on the rotating shaft, these are isolated from the electricity of the shaft, connected to the rotating coil; then there are carbon blocks that are performing pressure by means of springs, thus allowing electrical contact, the aforementioned blocks are the brushes.

Winding

A single-phase motor has two groups of windings in the stator: the first group is known as the main winding or working winding; the second is known as the auxiliary or start winding. These two windings are connected in parallel to each other, the line voltage is applied to both when energizing the motor.

Classification and Types of Electric Motors (Geared Motors, Electric Generators and Variable Speed Drives)

Classification of Electric Motors

Direct Current (DC) Motors

- Excitation Independent

- Excitation Series

- Excitation (shunt) or shunt.

- Compound excitation (compund)

Alternating Current (AC) Motors

- Synchronous Motors

- Asynchronous Motors

- Single-phase

- Auxiliary winding

- Short-circuited loop

- Universal

- Three-phase

- Wound rotor

- Short-circuit rotor (squirrel cage)

- Single-phase

Types of Electric Motors

Types of Electric Motor Machines

Geared motors

They are compact machines that combine an electric motor with a speed reducer, they are joined in one piece and are used to slow down various equipment automatically. The geared motor system has been perfected and that is why large industries use them in various processes. They are often used instead of DC motors, since the geared motor does the work and does not cause higher energy costs.

Electric Generators

Generators are rotating electrical machines that convert mechanical energy into electrical energy. This is due to the interaction of its components, the rotor and the stator. In the operation of these machines one of the two parts generates magnetic flux acting as an inductor, so that the other part transforms it into electricity, acting as the induced component. Two types of generators can be distinguished, the so-called alternators and dynamos, the former generate electricity by means of alternating current and the latter by means of direct current.

Variable Speed Drives

Also known as a variable speed converter, it is a component that allows the rotational speed of an AC motor to be controlled so that the frequency of the voltage applied to the motor can be regulated. By modifying the voltage you can avoid saturation of the magnetic flux with elevations that could damage the motor. These machines were designed to improve industrial processes and have been noted for their ability to provide torque, operate without mechanical shocks, carry out complex movements and adjust the production rate.

Electric motors are generally used in industrial sectors, but are also widely used in commercial and private sectors.

They are used in fans, cell phones, pumps, household appliances, tools, among many others. The smallest ones can be used in wristwatches. While the larger ones are used for propulsion of large vessels and pipeline compressors.

Electric motors are also popular in robotics. These are used to turn the wheels of vehicular robots, and servo motors are used to turn arms and legs on humanoid robots. In flying robots, along with helicopters, a motor causes a propeller or wide, flat blades to rotate and create the lifting force, allowing vertical movement.